Centrifugal pump vs turbine pump: Main differences

Modern pumps are used across industries and everyday settings to transfer water and other liquids. But the question often comes up: what’s the difference?

We’ll briefly explore a centrifugal pump vs turbine pump: drawing on our years of experience in item sales and expert selection, we will instruct you through picking the right device for your needs and highlight what really matters — from performance efficiency to overall trustworthiness.

Key Takeaways

Comparing a turbine pump vs centrifugal pump, you’ll find they share some similarities: both are used across industries and everyday household settings.

However, turbine parts are typically employed for deep well applications, while centrifugals are more versatile for a high flow rate.

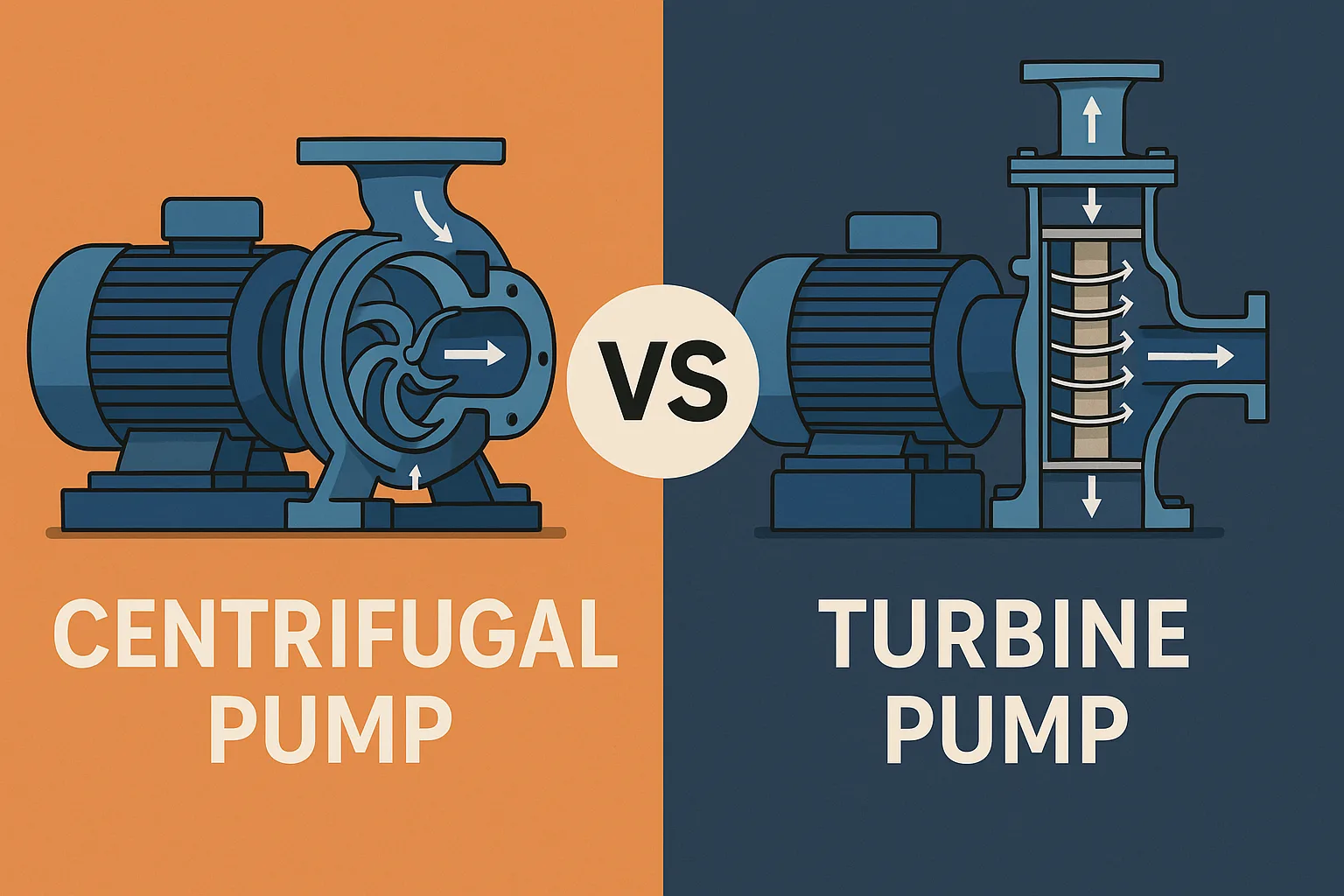

- Centrifugal models are fitted with a single impeller and create a radial flow. Turbine items are equipped with multiple impeller stages or a wheel that causes the liquid to circulate several times within the pump.

- As for operating and mechanical efficiency and turbine vs centrifugal pump cavitation control, the first type definitely holds a clear advantage. Booster systems deliver higher head, meanwhile, spinning models provide a higher water flow, maintaining high efficiency.

- The ease of maintenance also plays an important role: turbine pumps are primarily created for demanding conditions and require professional care, making them excellent for situations where a high head is needed. Radial models are very simple, much easier to operate, and are often used in household water supply, and circulation approaches.

Snapshot: What is a Turbine Pump?

Let us give you a snapshot: what is a turbine pump?

This modern equipment generates high pressure with a relatively low flow rate, thanks to its specific impeller design, which allows the flow force to build smoothly and rapidly as the fluid drives through each stage of the construction. They are suitable for industrial and domestic settings where water supply is planned from deep wells or boreholes.

From a fluid dynamics perspective, its staged energy transfer minimises friction and cavitation losses, boosting overall efficiency. This is expensive equipment, and there is an alternative — jet pumps with a stream flow through an ejector.

Quick Overview: What is a Centrifugal Pump?

Let’s take a gape at what is a centrifugal pump: a completely other type of device that generates centrifugal force by an impeller.

We get high tension and a compatible flow rate at the outlet with moderate force and steady reliability. But if your goal is high head, consider multistage pumps. They offer strong competition thanks to their power and low maintenance requirements.

When comparing turbine and centrifugal pump reliability, it’s the flow-driven design that offers users simplicity and efficiency, along with the ability to consistently and reliably manage everyday household tasks.

FAQ

Does the deepness of the well affect pump selection?

Yes, the deeper the well, the greater the need for power and strength.

How can I choose between a turbine and a centrifugal pump?

A turbine pump is superior for great depths, while a centrifugal pump is suited for household water supply and irrigation.

How can I compare a centrifugal pump vs turbine pump?

Centrifugal units move large volumes at moderate pressure, turbine devices generate high head with a lower flow.

Which pump is more reliable?

With correct installation and proper operation, both types are reliable and can successfully perform over a long period.

Conclusion

Comparing a regenerative turbine pump vs centrifugal pump, it’s clear that each class has its own purpose and strengths, whether it’s multi-stage operation, long service life, cost-effectiveness, or ease of maintenance.

Get in touch with our experts at Streamline Pump Solutions to find a cost-effective and reliable water supply for your home or business project.

Articles you may be interested in