Pressure Pumps

Showing 1–24 of 34 results

Reefe VSRM50 Variable Speed Pressure Pump 270 L/min 50m

Original price was: $3,470.00.$2,949.50Current price is: $2,949.50.Reefe VSRM58 Variable Speed Pressure Pump 130 L/min 58m

Original price was: $2,232.00.$1,897.20Current price is: $1,897.20.Reefe VSRM48-72 Variable Speed Pressure Pump 72L/min 47m hd

Original price was: $1,673.00.$1,422.05Current price is: $1,422.05.Reefe RHMS65 Horizontal Multistage Pump w Pressure Controller 180 L/min 65m

$1,870.00Reefe PRJ80 Pressure Pump 75 L/min 48m

$844.00Reefe PRJ65 Pressure Pump 70 L/min 40.5m

$597.00Reefe PRJ55 Pressure Pump 60 L/min 34m

$449.00Reefe RSWE120 Jet Pump 110 L/min 49.7m

Original price was: $705.00.$599.25Current price is: $599.25.Reefe EJP150E Self Priming Pump 80 L/MIN 64m

Original price was: $1,560.00.$1,326.00Current price is: $1,326.00.Reefe EJP200E Self Priming Pump 120 L/MIN 61m

Original price was: $1,780.00.$1,513.00Current price is: $1,513.00.Reefe EJP300E Self Priming Pump 150 L/MIN 60m

Original price was: $2,460.00.$2,091.00Current price is: $2,091.00.Reefe RSWE40 Jet Pump 50 L/MIN 35m

$495.00Reefe RSWE60 Jet Pump 100 L/min 49.5m

Original price was: $610.00.$518.50Current price is: $518.50.Reefe RHMS80-175 Multistage Pressure Pump 180 L/min 80m

$2,388.00Reefe RPS57E M/Stage Submersible Pump w Integral PC 90 L/min 57m

Original price was: $1,359.00.$1,155.15Current price is: $1,155.15.Reefe RPS34E M/Stage Submersible Pump w Integral PC 80 L/min 32m

Original price was: $1,145.00.$973.25Current price is: $973.25.Reefe RHMS92 Multistage Pressure Pump 120 L/min 92m

$1,669.00Reefe RHMS67 Multistage Pressure Pump 120 L/min 67m

$1,343.00Reefe RHMS52 Multistage Pressure Pump 110 L/min 52m

$1,088.00Reefe RHMS50 Multistage Pressure Pump 175 L/min 50m

$1,537.00Reefe RHMS46 Multistage Pressure Pump 350 L/min 46m

$2,210.00Reefe RHMS40 Multistage Pressure Pump 60 L/min 40m

$834.00Reefe PRT40E Turbine Pump & PC 40L/min 35m

$450.00Reefe PRJ052 Pressure Pump 55 L/min 33m

Original price was: $549.00.$449.00Current price is: $449.00.

Pressure pumps: Types of Classification

Each type of pressure pump is designed to handle distinct tasks, from boosting water pressure in homes to managing the heavy-duty demands of industries like oil and gas.

Self-Priming Regenerative Pumps

They often come equipped with electronic controllers that can be installed to automate the operation. Additionally, these aggregates may be used in irrigation systems, maintaining consistent water flow across large gardens or agricultural fields. Their ability to work efficiently with different liquid types makes them ideal for industrial settings where reliability and flexibility are essential. In challenging conditions, their low-maintenance requirements and energy-friendly operation make them a top choice.

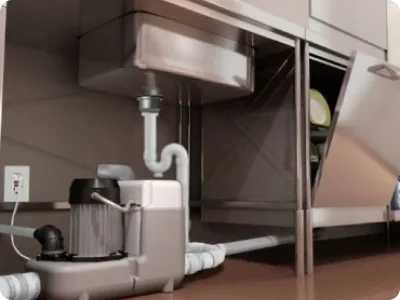

Centrifugal and Submersible Pumps

Submersible pumps are highly versatile, and designed to operate while fully submerged in water, which eliminates the need for priming. These aggregates are commonly used for residential purposes, such as draining flooded basements or pumping rainwater from wells. They are a preferred option in groundwater harvesting systems due to their ability to efficiently manage large water volumes without needing to draw the liquid through an external vessel. If you’re looking for more options in this category, you might also be interested in buying submersible pumps for other specialized applications.

Where Applicable

Pressure pumps are used across various industries and domestic settings. Their ability to regulate and boost water pressure makes them essential for homes, farms, and industrial plants.

Residential Use

In urban environments, pressure pumps are crucial for improving water flow, particularly in high-rise buildings where pressure gradually drops with height. Homeowners often need booster pumps to maintain consistent water pressure. These aggregates, often self-priming, ensure steady water flow for daily activities like using household appliances. Irrigation systems in home gardens also benefit from speed-controlled booster pumps, which adapt to the size of the space and water needs.

For more remote areas, submersible pumps are commonly installed to manage rainwater and groundwater harvesting. These aggregates are vital for drawing water from wells or underground sources, ensuring steady pressure in the household’s plumbing system.

Industrial and Specialized Use

Pressure pumps are critical in commercial and industrial settings for moving large liquid volumes efficiently. Centrifugal pumps are widely used in industries like oil, gas, and chemical processing, capable of handling high-speed liquid transfers. In large agricultural operations, pressure aggregates are key for irrigation, where booster pumps help maintain water pressure regardless of terrain or field size.

For deep well applications, borewell compressor pumps are used to draw water from significant depths. These pumps often feature electronic controls for precise operation, ensuring they meet the high demands of industrial-scale liquid transfers. The inclusion of vessels to store and regulate water helps stabilize pressure in fluctuating environments, making these systems highly reliable. If you need pumps for this purpose, consider engine driven pumps, which offer powerful performance for tough conditions.

How to Choose Correctly

Selecting the right pressure pump involves evaluating several factors, including the specific use case, flow rate, and power source.

Consider Pressure, Flow Rate, and Power Source

The power source is also critical, as many aggregates run on electricity, though solar or gas-powered options are available for areas with limited electrical supply. For more remote settings, solar-powered pumps can be installed, offering an energy-friendly and sustainable solution for groundwater management.

Budget and Maintenance

Initial costs for pressure pumps can vary, but it’s important to consider long-term maintenance. Aggregates like submersible and self-priming models typically require less upkeep, making them cost-effective over time. In contrast, systems that include additional components, like vessels for water storage or controllers for regulating flow, may have higher upfront costs but offer more configurable solutions for complex needs. When evaluating costs, consider both the initial investment and long-term reliability.

Additionally, it’s important to evaluate the power source when selecting a pressure pump. Depending on your location, you may require an electric-powered aggregate or consider alternative energy sources such as solar or gas. In remote areas where electricity is limited, solar or gas-powered pumps offer a viable solution. In cities, electric pressure pumps are the most commonly used, as they offer reliable and cost-effective performance. Some modern systems like the aquajet-inox also come equipped with advanced features, making them suitable for a wide range of applications. Integrating a buffer system can also help manage pressure fluctuations in such setups, ensuring smooth operation as variable speed pumps.

On the other hand, submersible pumps and booster aggregates typically require less maintenance, making them a more cost-effective choice over time. Although they may have a higher upfront cost, their durability and low maintenance needs often make them more economical in the long run. Factoring in both the initial investment and ongoing maintenance will help ensure that you select a pressure pump that meets your requirements and fits within your budget. Modern systems like the d-econcept further enhance cost-effectiveness by offering energy-friendly solutions.

How to Order

If you’re ready to buy pressure pumps, you can easily purchase them online or through local retailers.

Research Reputable Sellers

Before placing an order pressure pumps price in Australia, research suppliers offering competitive pressure aggregates price. Look for warranties and customer reviews to ensure the product meets your expectations. For precise measurement and efficiency tracking, consider purchasing a pump with an existing meter already integrated.

Online and Local Retailers

You can find pressure aggregates available online through various retailers. For those looking for pressure pumps in the city, visiting local suppliers allows you to inspect the product firsthand and discuss specifications directly with experts.

By considering these factors, you’ll be well-equipped to make an informed decision and buy pressure aggregates suited to your specific needs.