Multistage Pumps

Showing 1–13 of 13 results

Reefe VSRM50 Variable Speed Pressure Pump 270 L/min 50m

Original price was: $3,470.00.$2,949.50Current price is: $2,949.50.Reefe VSRM58 Variable Speed Pressure Pump 130 L/min 58m

Original price was: $2,232.00.$1,897.20Current price is: $1,897.20.Reefe VSRM48-72 Variable Speed Pressure Pump 72L/min 47m hd

Original price was: $1,673.00.$1,422.05Current price is: $1,422.05.Reefe RHMS65 Horizontal Multistage Pump w Pressure Controller 180 L/min 65m

$1,870.00Reefe RHMS40 Multistage Pressure Pump 60 L/min 40m

$834.00Reefe RHMS46 Multistage Pressure Pump 350 L/min 46m

$2,210.00Reefe RHMS50 Multistage Pressure Pump 175 L/min 50m

$1,537.00Reefe RHMS52 Multistage Pressure Pump 110 L/min 52m

$1,088.00Reefe RHMS67 Multistage Pressure Pump 120 L/min 67m

$1,343.00Reefe RHMS80-175 Multistage Pressure Pump 180 L/min 80m

$2,388.00Reefe RHMS92 Multistage Pressure Pump 120 L/min 92m

$1,669.00Reefe RHMS38 Multistage Pressure Pump 110 L/min 38m

$1,034.00Reefe RHMS78-120 Multistage Pressure Pump 120 L/min 78m

$1,512.00

Types of Classification of Multistage Pumps

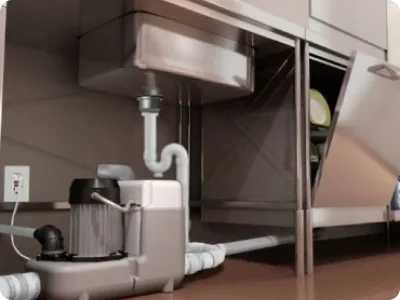

Horizontal Multistage Pumps

Vertical Multistage Pumps

Unlike horizontal pumps, vertical pumps feature a vertical impeller arrangement, resulting in a smaller installation footprint. This design makes aggregates ideal for high-pressure applications requiring compact systems, such as high-rise buildings and large-scale cooling systems. These aggregates are widely used to boost water pressure in limited-space environments and serve key roles in industrial processes like reverse osmosis, irrigation, and fire protection. With their versatility, vertical pumps are a preferred choice for water pressure applications in confined areas.

Where Multistage Pumps Are Applicable

Industrial Applications of Multistage Pumps

Residential and Commercial Uses

In residential and commercial environments, multistage aggregates are frequently used for water supply and pressure-boosting systems, serving buildings such as apartments, hotels, and office complexes. High-rise buildings especially benefit from aggregates, as they effectively deliver water to higher floors with steady pressure. Additionally, these aggregates are popular in HVAC systems, ensuring efficient water flow for heating and cooling in larger commercial buildings and supporting irrigation systems for landscaping.

How to Choose the Correct Model for Multistage Pumps

Key Features to Consider

When selecting a multistage pump, key factors like power, pressure, and the number of stages are essential. The aggregate power should align with the demands of the application, while its pressure capacity is crucial for meeting specific flow requirements. The number of stages in aggregates affects the pressure produced; more stages result in higher output, which is ideal for applications needing substantial pressure at moderate flow rates.

Energy Efficiency and Maintenance

Energy efficiency is critical, as it reduces operational costs and the environmental footprint. Choosing energy-efficient multistage aggregates minimizes electricity consumption, while ease of maintenance is also essential to reduce downtime. Pumps designed for easy access streamline repairs and component replacement, benefiting both industrial and commercial applications.

How to Order Multistage Pumps from Streamline Pump Solutions

Simple Ordering Process

Customers can easily navigate the website to order multistage pumps from Streamline Pump Solutions, which offers step-by-step guidance on selecting the best product for their needs. Consultations with aggregate specialists are available to ensure the chosen model meets technical requirements. Streamline Pump Solutions also provides technical support, making it easy for customers unfamiliar with aggregate specifications to order multistage pumps with confidence.

Except Multistage Pumps, we have such categories of pumps:

Consider checking them as well.

Delivery and Customer Support

Streamline Pump Solutions ensures secure and timely shipping across Australia. Alongside delivery, customers benefit from comprehensive post-purchase support, including assistance with installation, maintenance, and troubleshooting. The dedicated support team at Streamline provides expert advice to ensure long-lasting performance and customer satisfaction.